AMPED EFRC Research Capabilities & Facilities

The mission of the Alliance for Molecular PhotoElectrode Design for Solar Fuels (AMPED) is to develop the fundamental molecular basis for solar-driven water oxidation and carbon dioxide reduction catalysis. In support of this mission the AMPED EFRC has established world-class user facilities in Spectroscopy, Materials Fabrication & Characterization, Photolysis & Solar Fuels Product Analysis, and Synthesis.

Every facility is available to all members of the EFRC, who can work with staff in a collaborative mode, or become trained for independent use of the instrumentation. The capabilities and staff support provided in the AMPED EFRC facilities, combined with those in the Chapel Hill Analytical and Nanofabrication Laboratory, CHANL, provide an extraordinarily powerful support environment enabling rapid progress on difficult, multi-dimensional problems. For example, it is possible for a synthetic chemist to modify an oxide surface with a new assembly, assess interfacial dynamics, characterize surface structure by analysis and imaging, test the assembly within a device configuration, and have theory assistance with data interpretation, all in a matter of days.

SPECTROSCOPY FACILITY

A significant challenge for solar energy research is developing a unified picture of the dynamics that occur following light absorption, characterizing the processes that not only lead to fuel production, but also recombination events that limit efficiency. The ability to observe and elucidate photo-induced events on time scales ranging from femtoseconds to seconds, within assemblies, nanostructures, and molecular systems, both in solution and on surfaces requires a broad array of experimental capabilities. The Spectroscopy Facility houses instrumentation for steady-state and time-resolved absorption, emission, and Raman measurements. It supports ancillary efforts in femtosecond Raman spectroscopy, transient grating, visible-pump transient absorption spanning fs-ms time scales, and time-resolved emission microscopy by time-correlated single photon counting.

MATERIALS & ELECTRODE FABRICATION FACILITY

The AMPED EFRC Device Fabrication and Characterization Facility is dedicated to materials and device fabrication and has two main functions:

- Development and preparation of semiconductor nanoparticle thin films and electrodes to be used by researchers throughout the Center.

- Standardization and large-scale reproducibility of high surface area semiconductor thin films and electrodes.

This facility is comprised of two laboratories: the Electrode Fabrication Laboratory, Fab Lab, and Solar Laboratory, SL:

The Electrode Fabrication Laboratory (Fab Lab), brings together equipment for materials synthesis and device fabrication/testing. AMPED EFRC researchers use the Fab Lab to synthesize nanoparticles by sol-gel methods and to prepare nanoparticle-polymer pastes for thin film deposition by a doctor-blade method or by spin-coating. High surface area conductive nanoparticle thin films are fabricated as substrates for spectroelectrochemical evaluation of molecular water oxidation catalysts and as support structures for performing electrocatalysis. Highly reproducible metal oxide films are fabricated by screen printing and by spray pyrolysis, for dense thin film metal oxide coatings. Key variables controlling batch-to-batch variation are characterized by Brunauer–Emmett–Teller, BET, surface area and pore size analysis, profilometry, TEM, FESEM, and UV-Vis. Quantification of key variables has formed the basis for scale-up and large-scale manufacture of high surface area semiconductor thin films. Characterization methods include IPCE, current-voltage, and Electrochemical Impedance Spectroscopy EIS. These experiments are complemented by transient photocurrent studies performed in the AMPED EFRC spectroscopy facility.

The Solar Laboratory (SL), provides cleanroom, class 1000, research conditions, essential for optimizing electrical performance, reproducibility and reliability of fabricated samples and devices, and houses a stand-alone photovoltaic fabrication/characterization system that includes an array of optical tools under an inert atmosphere. A train of inert atmosphere gloveboxes house a vacuum deposition module, spin-coater, high resolution microscope, and computer-controlled optical goniometer interfaced with a monochromator and solar simulators.

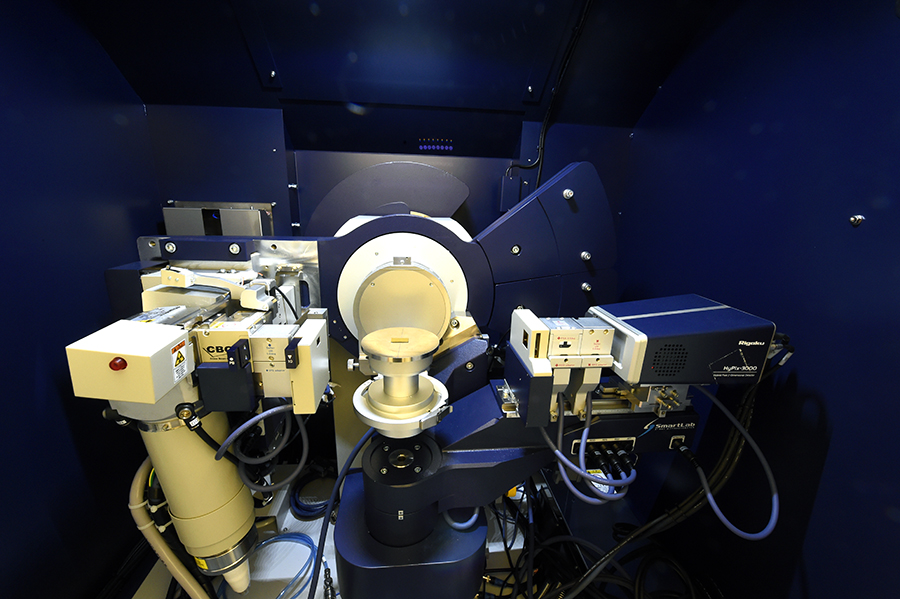

The AMPED EFRC leverages equipment in the Chapel Hill Analytical and Nanofabrication Laboratory, CHANL, a multi-department, core user facility at UNC that provides access to a broad array of analytical and nanofabrication instrumentation including EDS-TEM, EDS-SEM, AFM, XPS, UPS, ALD, PLD, and PECVD.

SYNTHESIS FACILITY

The AMPED EFRC supports efforts in synthesis and characterization of chromophores, catalysts and assemblies and the development of linker technologies. This includes scale-up synthesis of key compounds needed to support ongoing projects in water oxidation, carbon dioxide reduction, polymers, molecular assemblies, and devices.

The Center synthesis capability has provided a source for common starting reagents, for example functionalized ligands, that are not commercially available, freeing researchers to conduct research without dealing with repetitive and high-volume synthetic protocols.

PHOTOLYSIS AND SOLAR FUELS PRODUCT ANALYSIS FACILITY

This facility brings together the equipment necessary to characterize light-driven reactions with an emphasis on solar fuels production. Multiple light-soaking workstations are available. Solar fuels production is monitored using a variety of methods, including O2 sensors, GC and GC/MS. Importantly, we have constructed a capability that allows for real-time, definitive detection of oxygen while monitoring light-driven water splitting reactions in a dye-sensitized photoelectrosynthesis cell by taking advantage of a rotating ring-disk electrode configuration.